The performance and lifetime of materials widely used in energy and nuclear technologies are often severely limited by corrosion under stress loads. Particularly important for the DOE are environmental degradations of nickel-based alloys in advanced nuclear reactors and in glass containers of nuclear waste.

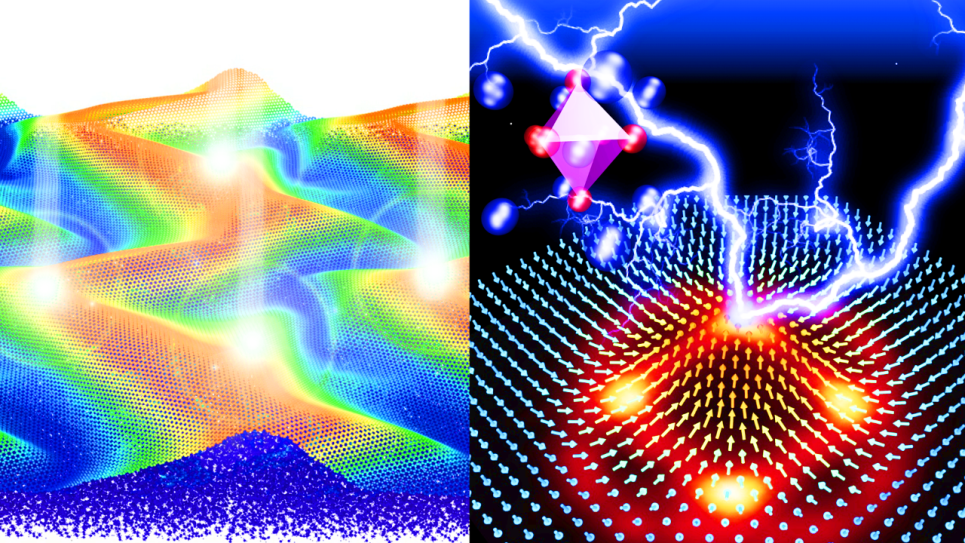

This team performs petascale reactive molecular dynamics (MD) and quantum mechanical (QM) simulations to investigate fundamental mechanisms of stress corrosion cracking (SCC) and nanoindentation of silica glass in the presence of water as well as impurity segregation-induced embrittlement of nickel-aluminum alloys.

In order to prevent SCC and to predict the lifetime beyond which SCC may cause failure, the petascale hierarchical simulation approach is used to discover:

- The role of water in nanoindentation damage of silica glass;

- Fundamental mechanisms of SCC in silica glass in the presence of water; and

- Atomistic mechanisms of impurity (sulfur and boron)-segregation induced embrittlement in nickel-aluminum alloys.

In the first year of the project, the team performed a billion-atom reactive MD simulation to study silica-water chemistry at a nanoindent on a silica surface generated by the collapse of a cavitation nanobubble in water, thus revealing the role of water in nanoindentation damage. In 2012, the team will carry over this knowledge to large-scale QM and reactive MD simulations to identify fundamental mechanisms of SCC in silica glass in the presence of water. The simulations of silica glass in the presence of water will be based on interatomic potentials that incorporate reactive processes involving bond breaking and bond formation as well as dynamic atomic charges that change with changes in the local atomic configurations. This will determine changes in the structure and surface energy of silica glass in the presence of water. Accelerated MD simulations will be performed to determine the dependence of the cracking initiation load in water.