The realization of fusion as a practical, 21st Century energy source requires improved knowledge of material surfaces and their interaction with the fusion material. In current fusion reactor designs, fusion energy is created from the fusion of hydrogen into helium atoms. In a reactor, fusion occurs in an extremely hot helium-hydrogen plasma that necessarily interacts with the material of the containment vessel. For successful design of a fusion reactor the interaction of this hot plasma on the containment material must be understood for successful materials engineering design.

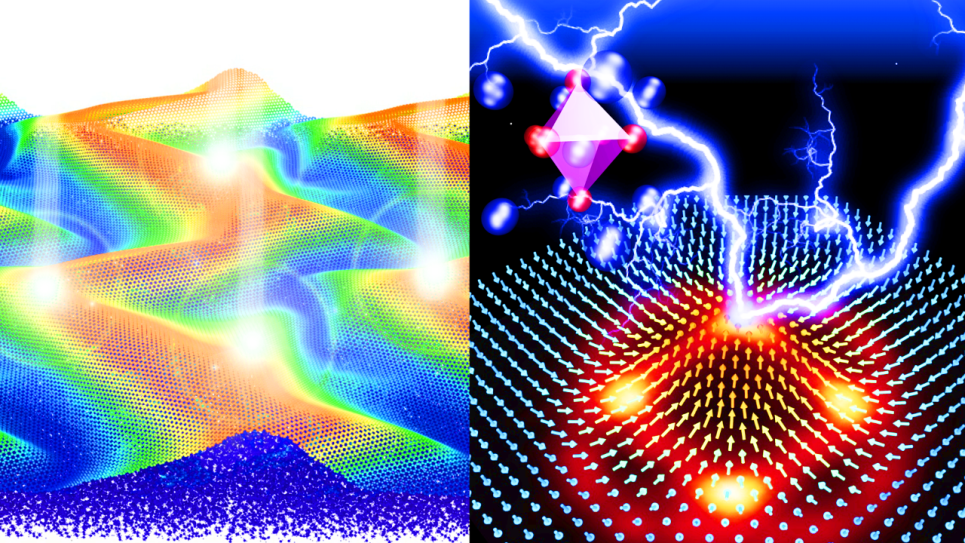

This allocation supports simulations to advance understanding of the response of tungsten, the proposed material for the ITER (an under-construction fusion reactor) divertor, to low energy helium and hydrogen plasma exposure. Knowledge of these interactions is necessary to identify materials design strategies to effectively manage high gas exposures expected in the fusion energy environment, and to quantify the expected inventory of radioactive tritium stored within the plasma facing components. This project will perform simulations at both the atomistic and continuum scale for comparison and benchmarking, as well as the identification of appropriate reduced-parameter models to describe complex, multiscale phenomena controlling gas behavior in fusion materials. The outcome will be a greater physical understanding and predictive modeling capability for materials design of the divertor for ITER.