SiO2 Fracture: Chemomechanics with a Machine-Learning Hybrid QM/MM Scheme

The fracture of silica is a problem that affects many diverse applications. In the mining industry, crushing and grinding mineral ores into fine power is an extremely energy-intensive process. In the biomedical realm, dental implants, for example, are made of silica-rich porcelain, which must survive years of tough mechanical work in the wet environment of the human body without breaking. A better understanding of the silica fracturing process could help address these issues, minimizing the energy cost required to fragment thousands of tons of rock and enabling the design of longer lasting prosthetic implants.

The underlying processes that cause silicates to crack in these applications are “chemomechanical”-- where stress fields and chemistry are tightly coupled. This is a very complex multiscale problem that can only be addressed with the computational power of the DOE’s leadership-class supercomputers and highly efficient algorithms.

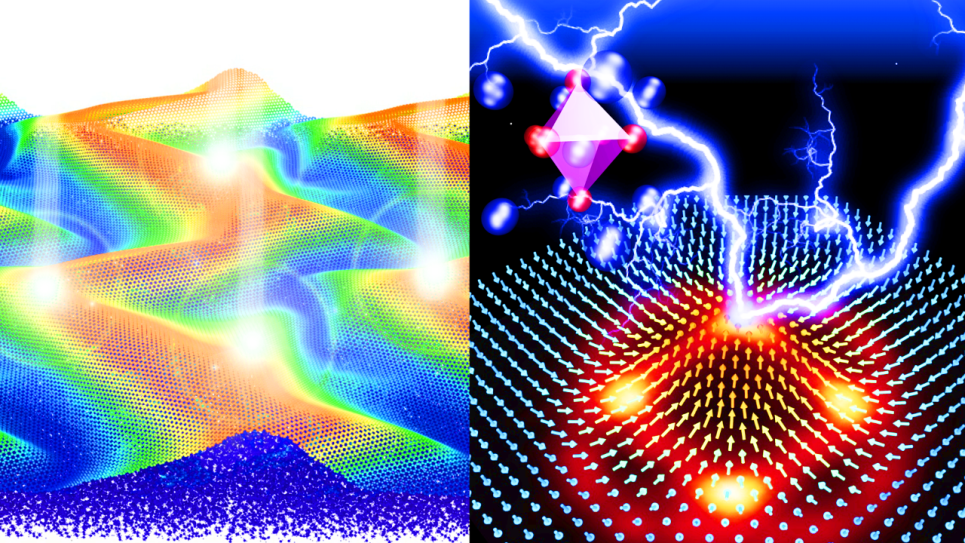

For this INCITE project, researchers will use Mira, the ALCF's Blue Gene/Q supercomputer, to further the understanding of how silicate materials break in an oxidizing or wet environment, following stress corrosion patterns. To do so, they will use advanced multiscale atomistic computer simulations based on molecular dynamics (MD) and machine-learning techniques. This includes applying the “Learn on the Fly” (LOTF) hybrid quantum mechanical/molecular mechanical (QM/MM) scheme to model fracture in silicone dioxide (SiO2). LOTF is a nonuniform, precision MD scheme which augments MM force fields with QM information, only where and when this is necessary to ensure accurate MD trajectories.

The project aims to deliver the first series of efficient QM-accurate 3D simulations of catastrophic and stress-corrosion-induced fracture in crystalline and amorphous silica. The work will also demonstrate the power of a new general, predictive software tool to help other research projects achieve quantum mechanical accuracy when needed.