Corrosion is a complex technological and economic problem with an annual cost of about 3% of the nation’s gross domestic product. The performance and lifetime of materials widely used in energy and nuclear technologies are often limited by corrosion under stress loads. Simulations performed at the Argonne Leadership Computing Facility are revealing the atomistic mechanisms that control stress-induced corrosion within nuclear reactors—which is key to understanding stress corrosion cracking (SCC), and ultimately, to developing new technologies to prevent it.

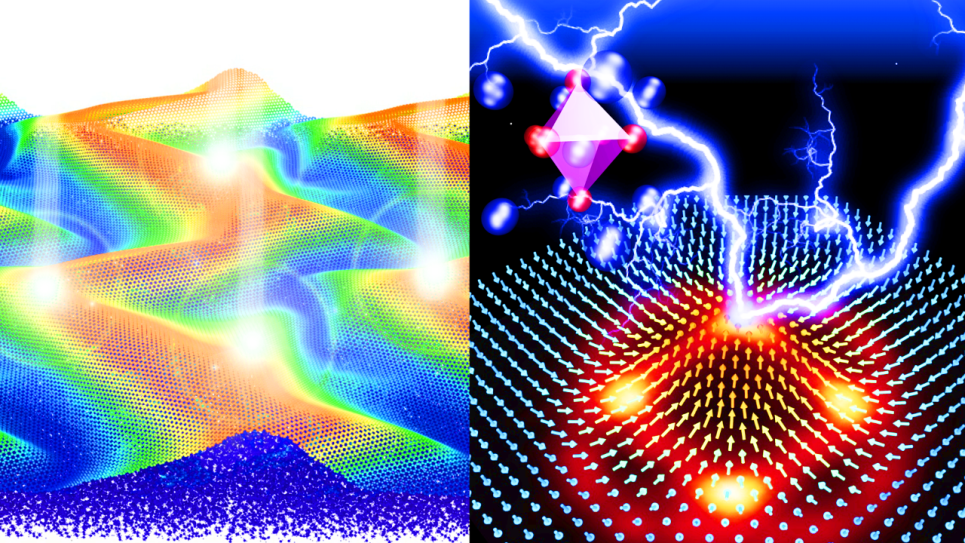

Researchers will study the complex electrochemical processes that lead to the degradation of nickel-based alloys and silicate glass. Molecular dynamics (MD) simulations will be used to help understand how a small amount of impurities within these materials can cause fractures and potentially catastrophic failures. These petascale quantum mechanical (QM) dynamics simulations will lead to an understanding of the atomistic mechanisms underlying SCC to better prevent such cracking and to predict the lifetime beyond which SCC may cause failure.

One of the simulation challenges lies at the QM/MD interface where the charge flow and bond-breaking events at the QM electronic scale are difficult to translate to the rigid bonding/fixed point charges regime usually used in the effective force-field MD approach. To facilitate this translation process, it would be advantageous to insert another computational method (i.e., first-principles based reactive force field), which has the ability to handle charge flow by employing a chemical environment-dependent model.

To prevent SCC and to predict the lifetime beyond which SCC may cause failure, requires an understanding of the atomistic mechanisms underlying SCC; that is, the conditions influencing initiation, dynamics, and growth rates of SCC. Ultimately, understanding of SCC will aid in the design of safe, next-generation nuclear reactors and nuclear waste containers.